Home

Welcome to our website! Explore and learn about our exciting, multifaceted activities at the Advanced Materials and Technologies Laboratory.

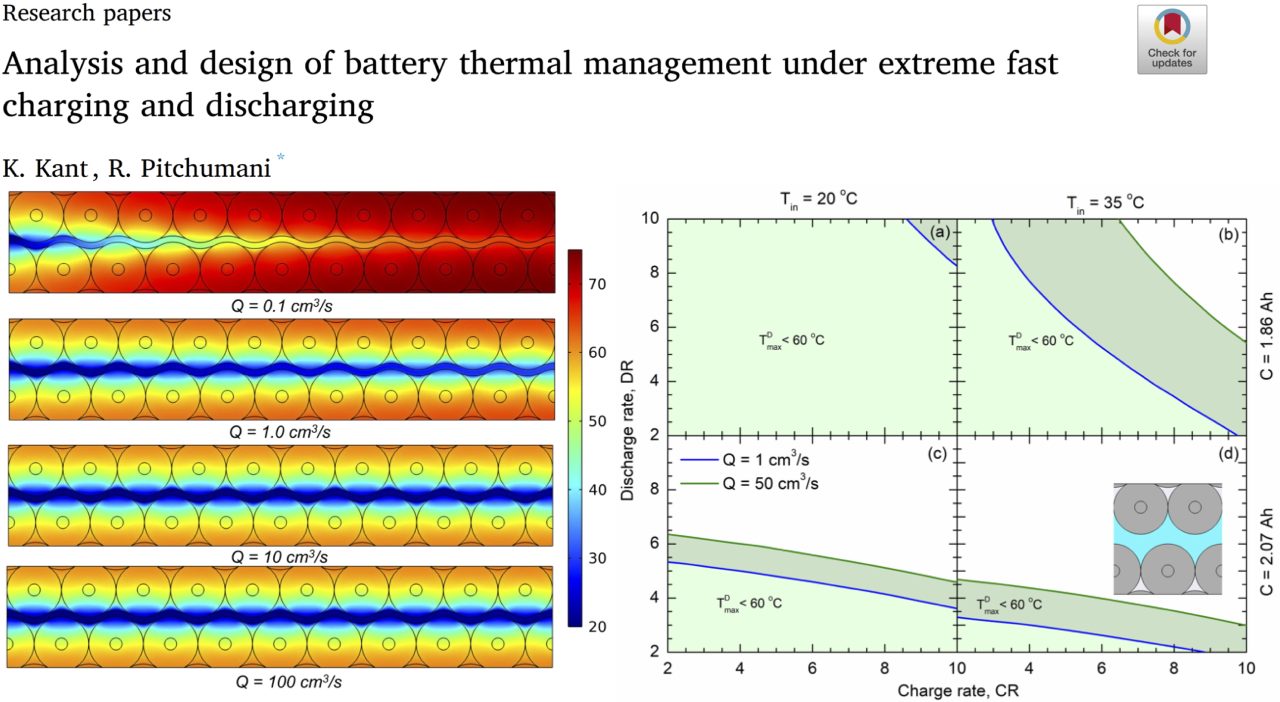

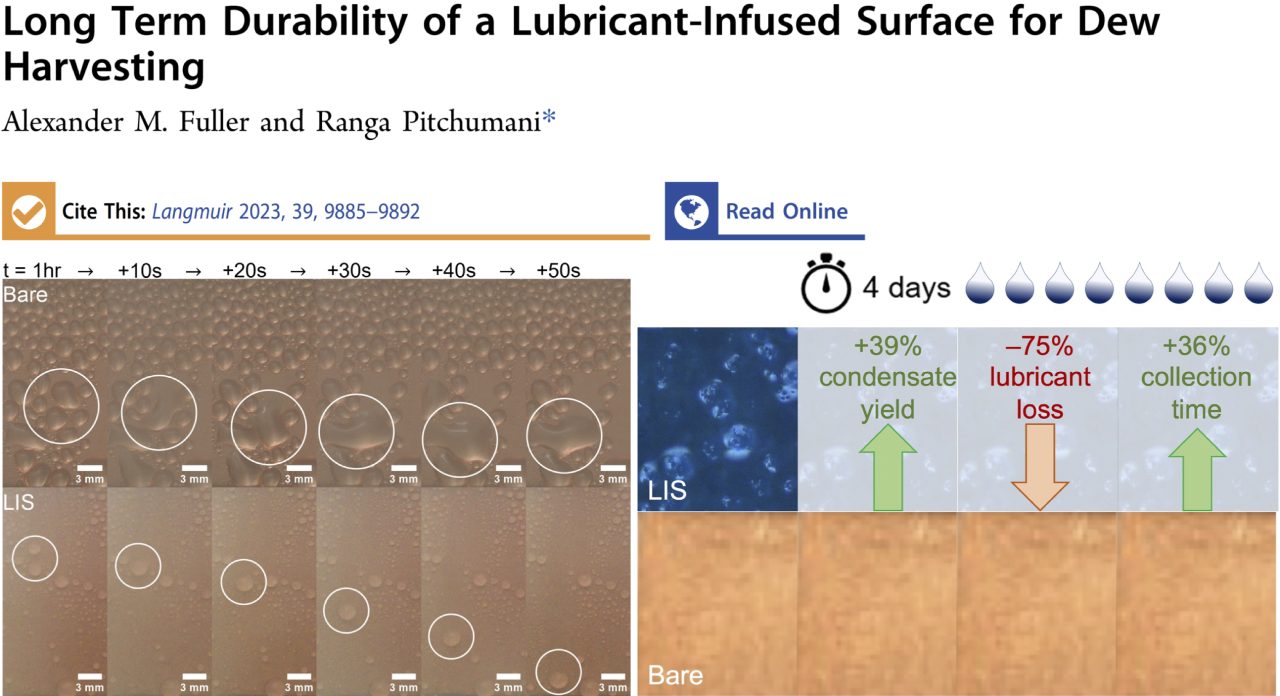

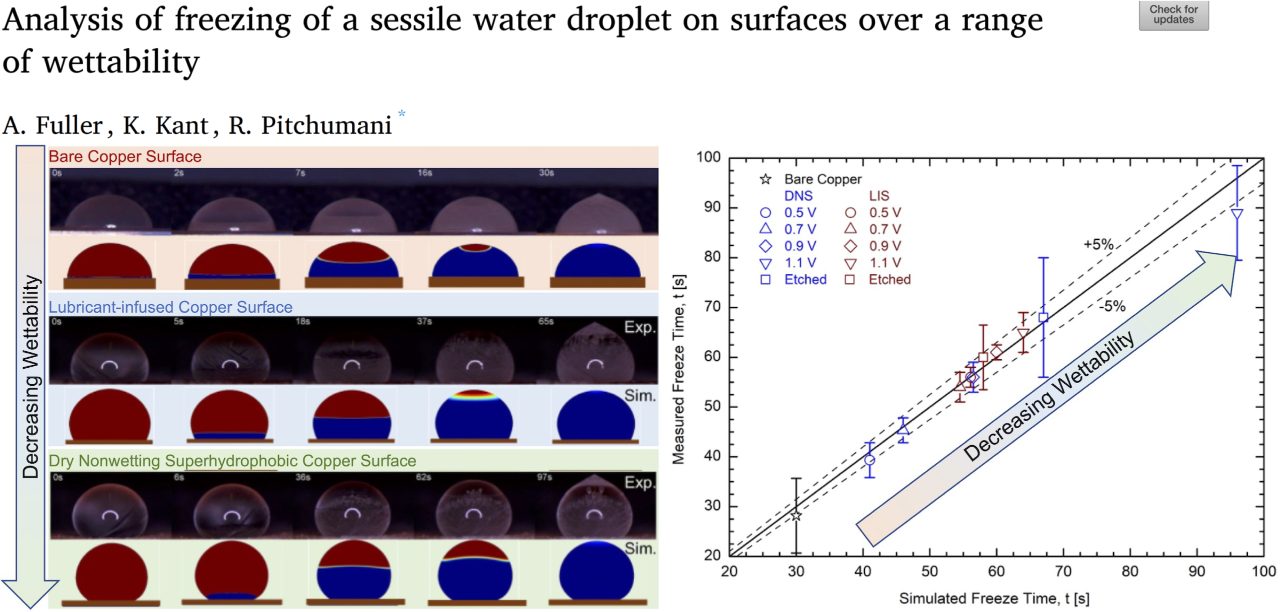

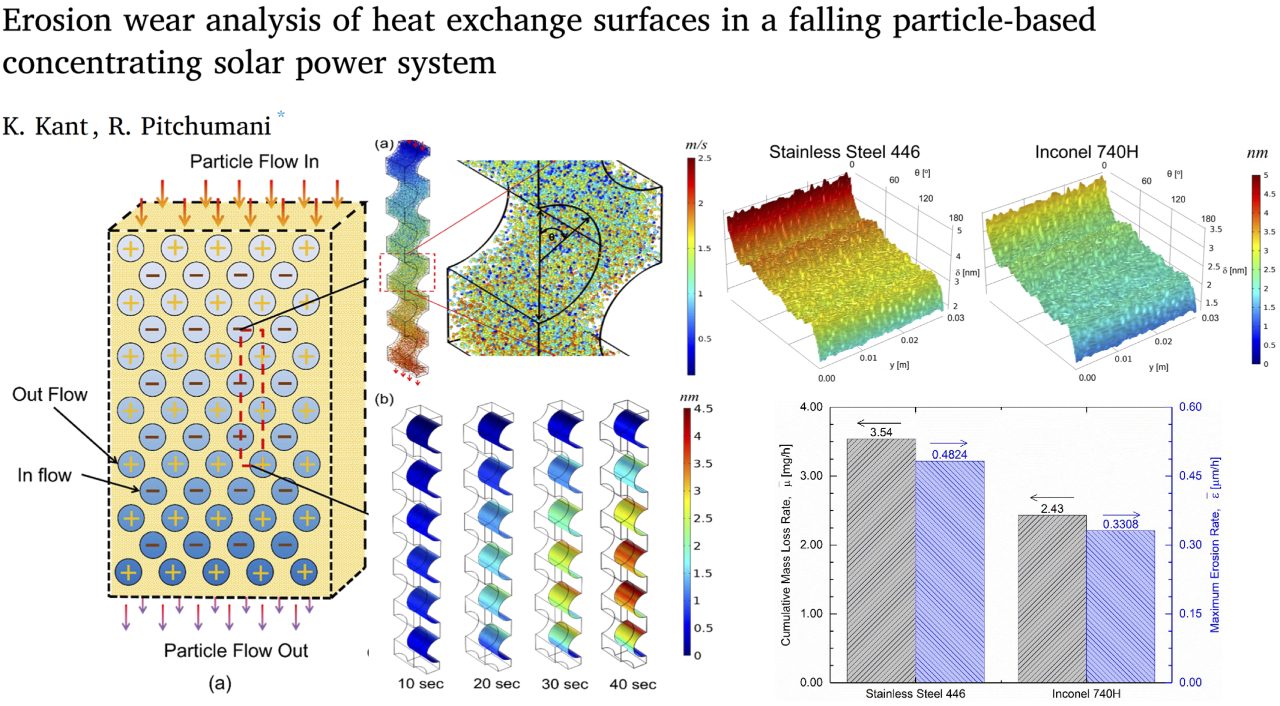

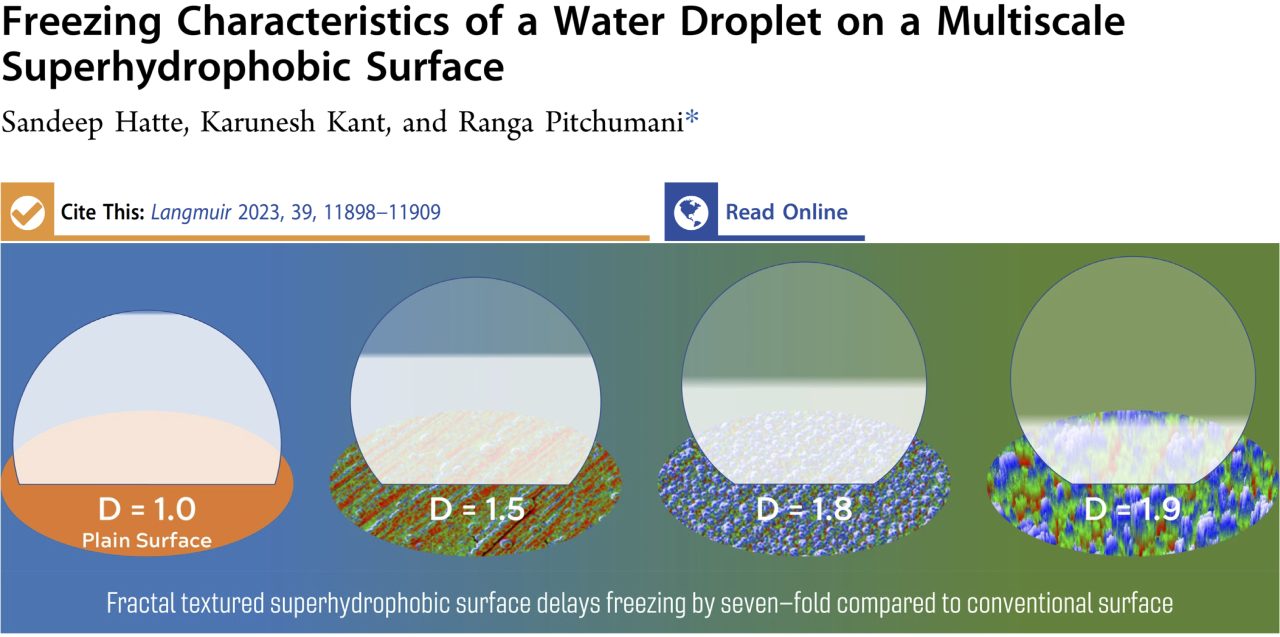

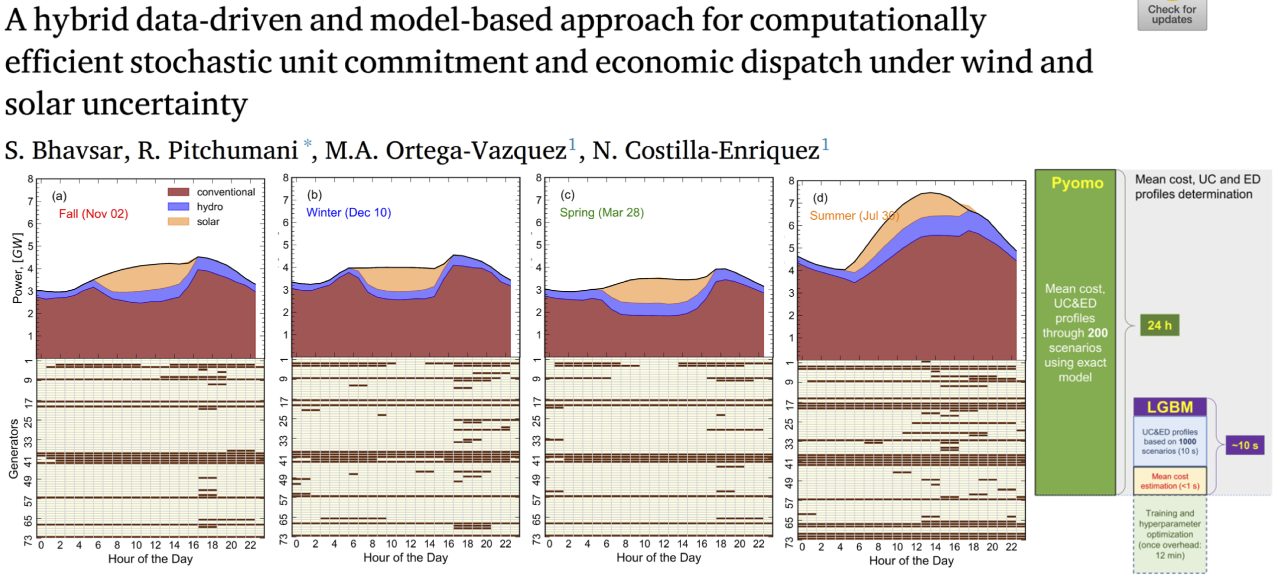

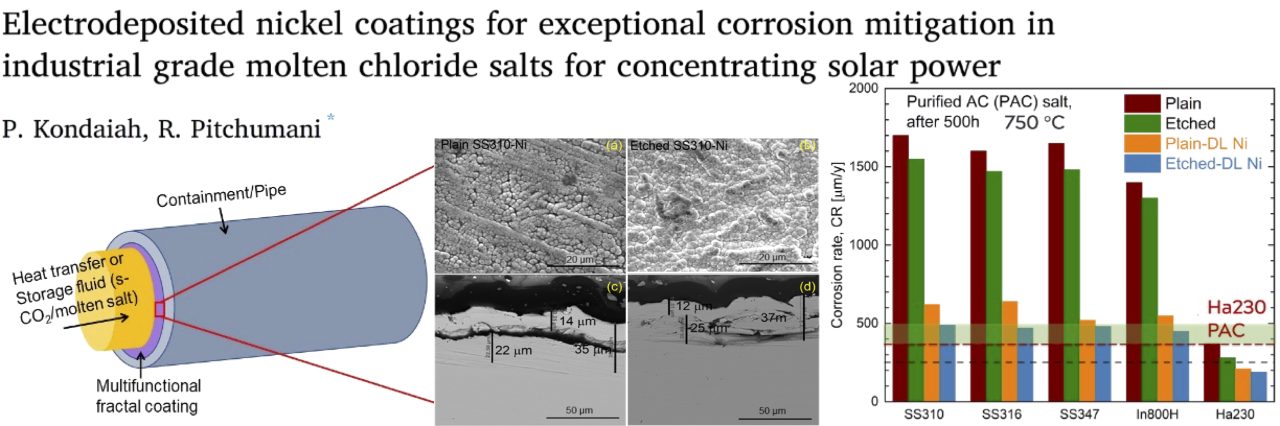

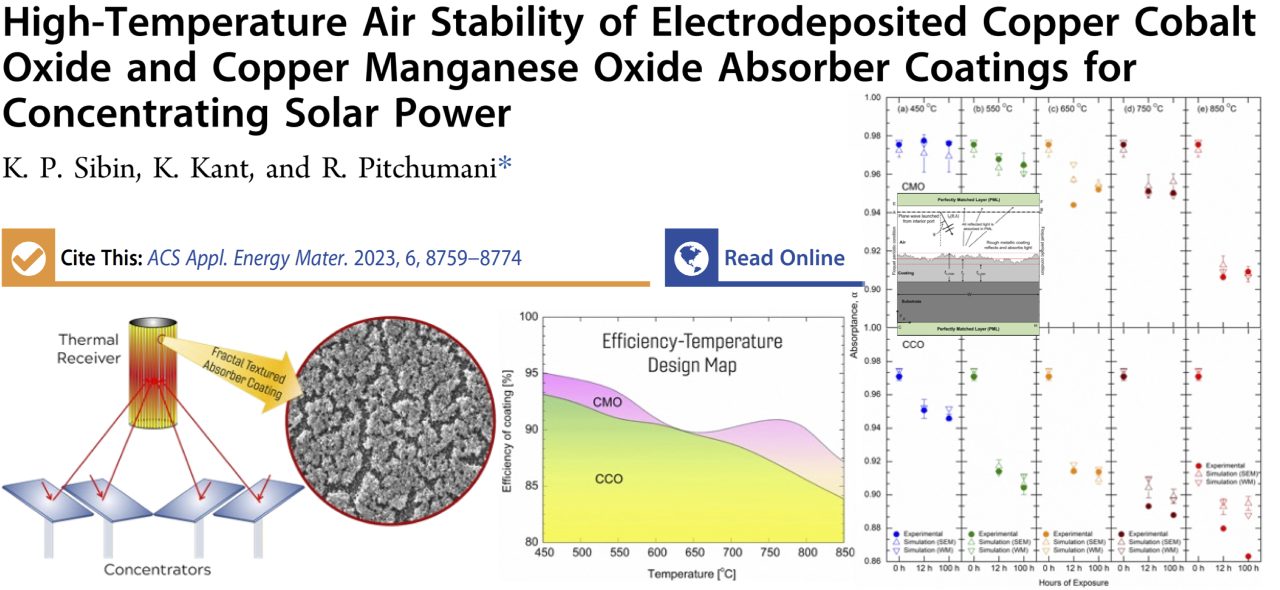

Organized in thematic research clusters, the projects focus on energy conversion and storage, energy/water nexus, electric grid integration of renewable energy; bio-inspired materials design and advanced materials processing (polymer, composite, ceramic materials); micro and nanotechnologies; uncertainty quantification and large-scale optimization. The emphasis is on developing a fundamental understanding of the complex physical phenomena through theoretical and experimental investigations, and bridging the fundamentals to research advances at the system level including technoeconomic considerations.

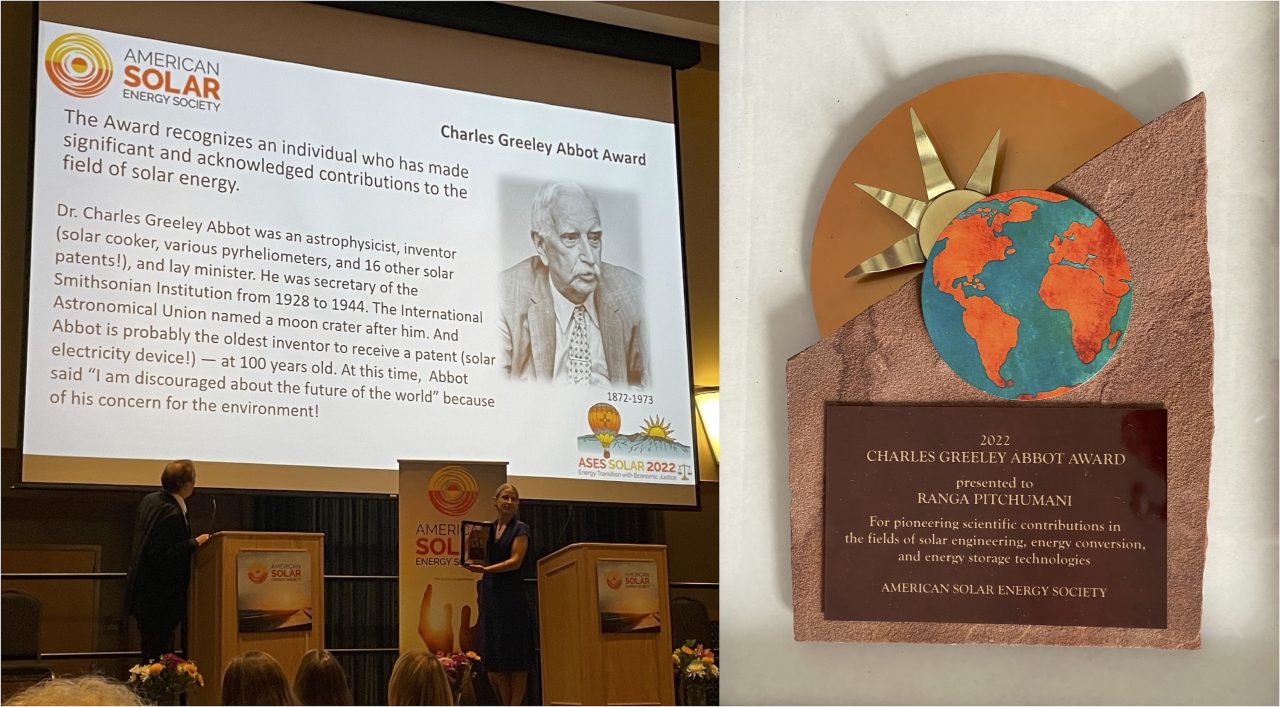

We work with several federal and industrial stakeholders who sponsor or partner in our research. To work with us, contact Prof. Ranga Pitchumani.

Sponsors and Partners